General

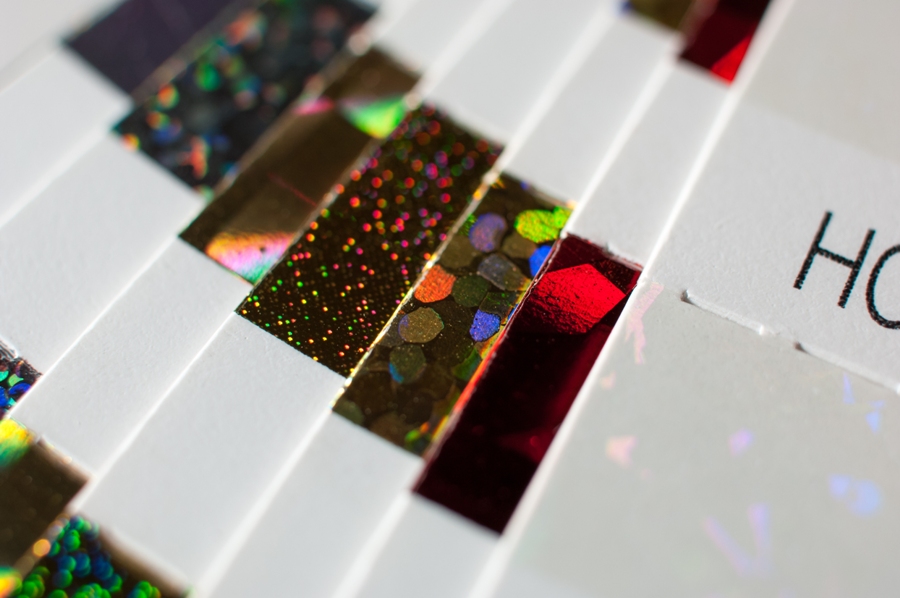

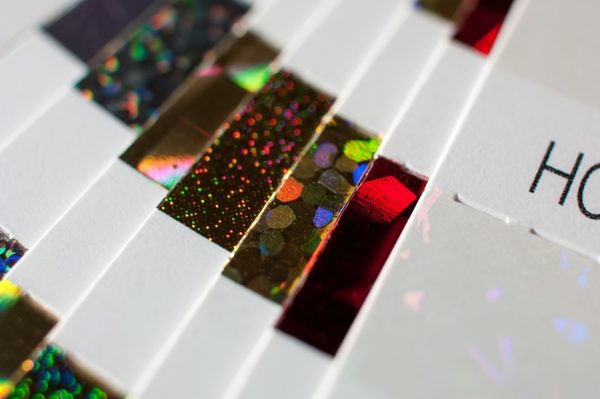

Beautiful Decorative Finishes And Glistening Metallic Marks

What Is Hot Foil Stamping?

Hot foil stamping is the process of applying metallic foil or holograms on different types of materials for diverse requirements. The technical method is reliant on the careful and calibrated application of the right amount of heat and pressure to various metallic substances, plastic, and laminated boards. The popular brass plates for hot foiling are a very reliable and versatile marking solution with widespread applications in different fields. The printers or stamping machines used in the process can deliver creative and glistening marks.

The heat and pressure dependent stamping refers to diverse activities that include –

- A simple and straightforward process of marking that relies on a flat foil.

- A combination of embossing or deep embossing and the traditional stamping.

- The very popular and appealing holograms and holographic applications.

- A mixture of micro embossing or structural embossing combined with hot foiling.

Popularity Of Brass In Marking

The modern printers, along with reliable materials such as brass and steel, can get the creative juices to flow. Decorative finishes and creative foiling embellishes the efficiency of diverse products related to packaging, cosmetics, publishing and manufacturing sectors. The brass plates for hot foiling, in particular, guarantees the following advantages –

- Brass is a hard and rust-free alloy which has golden sheen and attractive appearance.

- Plates and sheets made of this affordable metal go back to biblical times.

- The modern alloy making techniques ensure a very hard and high quality material.

- The alloy is relatively less expensive and the markings are cleaner, durable, and firm.

- It is one of the most popular design choices for commercial custom and type logos.

- The versatile applications include brand advertising, book binding, and wire marking.

Wide Ranging Applications

Modernity is symbolised by competitive spirit, commercial marketing, and designer quality products from manufacturers and sellers. Human technical skills and technological advances have increased the scope, variety and sophistication of various processes and foils have not been left behind. The best brass plates for hot foiling have wide spread popularity and the commercial applications are predominantly found in marketing and advertising segments.

The top quality foiling machines produce hot stamping and holographic foils, and brass is the predominant material used in dyes. These dyes themselves are produced by etching and manual engraving. Some advanced techniques rely on CNC machines to produce precise and high quality dies with custom designs and beautiful shapes. Some of the popular applications of foiling machines include –

- Publishers use them in business cards, wedding invitations, and greeting cards.

- Book covers, albums, journals, and book spines also have designer etchings.

- Cosmetic products such as leather belts, fashion bags, wallets and ribbons.

- Other applications are found in shoes, trainers, key rings, and photographic mounts.

Hot stamping and holograms require marking and the foil machines rely on heat and pressure. Versatile and designer quality embossing is achieved through technical skills and manual artistry. Metals are quite popular in dies and brass plates for hot foiling have a wide spread reach due to biblical history, range of applications, and beautiful appearance. The foil machines are indispensable in the production of designer quality book covers, shoes, cosmetics, birthday cards, and leather bags.

-

Tech11 years ago

Tech11 years agoCreating An e-Commerce Website

-

Tech11 years ago

Tech11 years agoDesign Template Guidelines For Mobile Apps

-

Business6 years ago

Business6 years agoWhat Is AdsSupply? A Comprehensive Review

-

Business10 years ago

Business10 years agoThe Key Types Of Brochure Printing Services

-

Tech8 years ago

Tech8 years agoWhen To Send Your Bulk Messages?

-

Tech5 years ago

Tech5 years ago5 Link Building Strategies You Can Apply For Local SEO

-

Law5 years ago

Law5 years agoHow Can A Divorce Lawyer Help You Get Through Divorce?

-

Home Improvement6 years ago

Home Improvement6 years agoHоw tо Kеер Antѕ Out оf Yоur Kitсhеn