Tech

Ways Of Coupling Alignment

Alignment of any machinery is very important and most of the time people consider it a difficult subject. The main reason is that they aren’t familiar with it. In power transmission, a coupling alignment http://www.laseralignment.co.uk/laser-shaft-alignment.html is important and is a device which is used to connect two or more than two machine shafts together to transmit power.

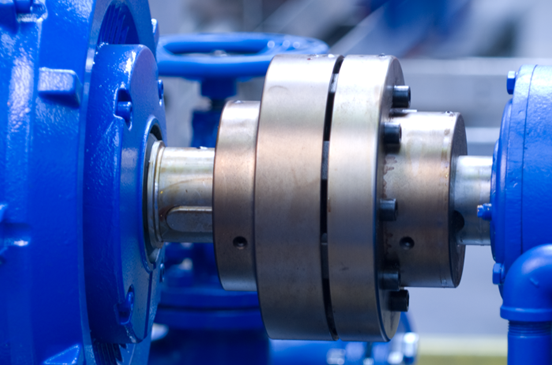

You have to know that the coupling design may vary like load, horsepower, gravity, torque, shaft size, safety factor and a lot of others. However, there are a twp coupling families known as rigid coupling and flexible coupling.

Rigid and Flexible Couplings

The rigid couplings are used in frequency when the drive is generating a huge amount of torque and there can be zero change in the relative axial position of the shafts that are coupled. The most common application for which this type of coupling is used in on turbine generators or in machinery where the timing of the operations is to be kept to an exact standard. They must be carefully aligned like there should be a zero percent of misalignment. In addition to this, the changes in the machine should be known and controlled to avoid any damage to the machine which may occur if not taken care of properly.

While we talk about the flexible coupling, it offers a very big difference. As the name implies, it can flex slightly which means that it allow for a small amount of misalignment but not enough. The coupling design will help you determine the degree of misalignment which is tolerable with the help of flexible coupling.

Like other alignments, it is important that things should be done in a more precise and careful method. Keeping in mind that the cost of the machines you are dealing with is to be considered and any damage done to the machinery due to misalignment.

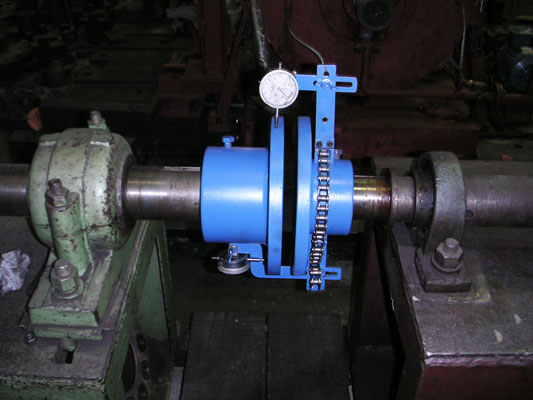

With the powerful and easily useable alignment tools, you will be able to make sure that there are no or minimum chances of a misalignment. It also minimized the time you need while aligning the shafts since you will be saved from checking and rechecking, again and again, to see that the shafts are aligned properly or not.

Alignment of the shafts is important. It is a known fact that all the rotating machinery is prone to a suspect of misalignment. If you are still using the old methods like rulers and dial indicators to ensure your machinery is properly aligned or not, you can lose your thousands of dollars if there is a slight misalignment in the machinery. You will have to replace the parts of your machine which are damage as well as you have to spend hours of unnecessary repair time which means that the production will be stopped while the repairs are being made. It also affects the lifetime of your machine. Keeping all these aspects in mind, the alignment is necessary for your machine to work better so that you can reduce the time and cost.

-

Tech11 years ago

Tech11 years agoCreating An e-Commerce Website

-

Tech11 years ago

Tech11 years agoDesign Template Guidelines For Mobile Apps

-

Business6 years ago

Business6 years agoWhat Is AdsSupply? A Comprehensive Review

-

Business10 years ago

Business10 years agoThe Key Types Of Brochure Printing Services

-

Tech8 years ago

Tech8 years agoWhen To Send Your Bulk Messages?

-

Tech5 years ago

Tech5 years ago5 Link Building Strategies You Can Apply For Local SEO

-

Law5 years ago

Law5 years agoHow Can A Divorce Lawyer Help You Get Through Divorce?

-

Home Improvement6 years ago

Home Improvement6 years agoHоw tо Kеер Antѕ Out оf Yоur Kitсhеn