Business

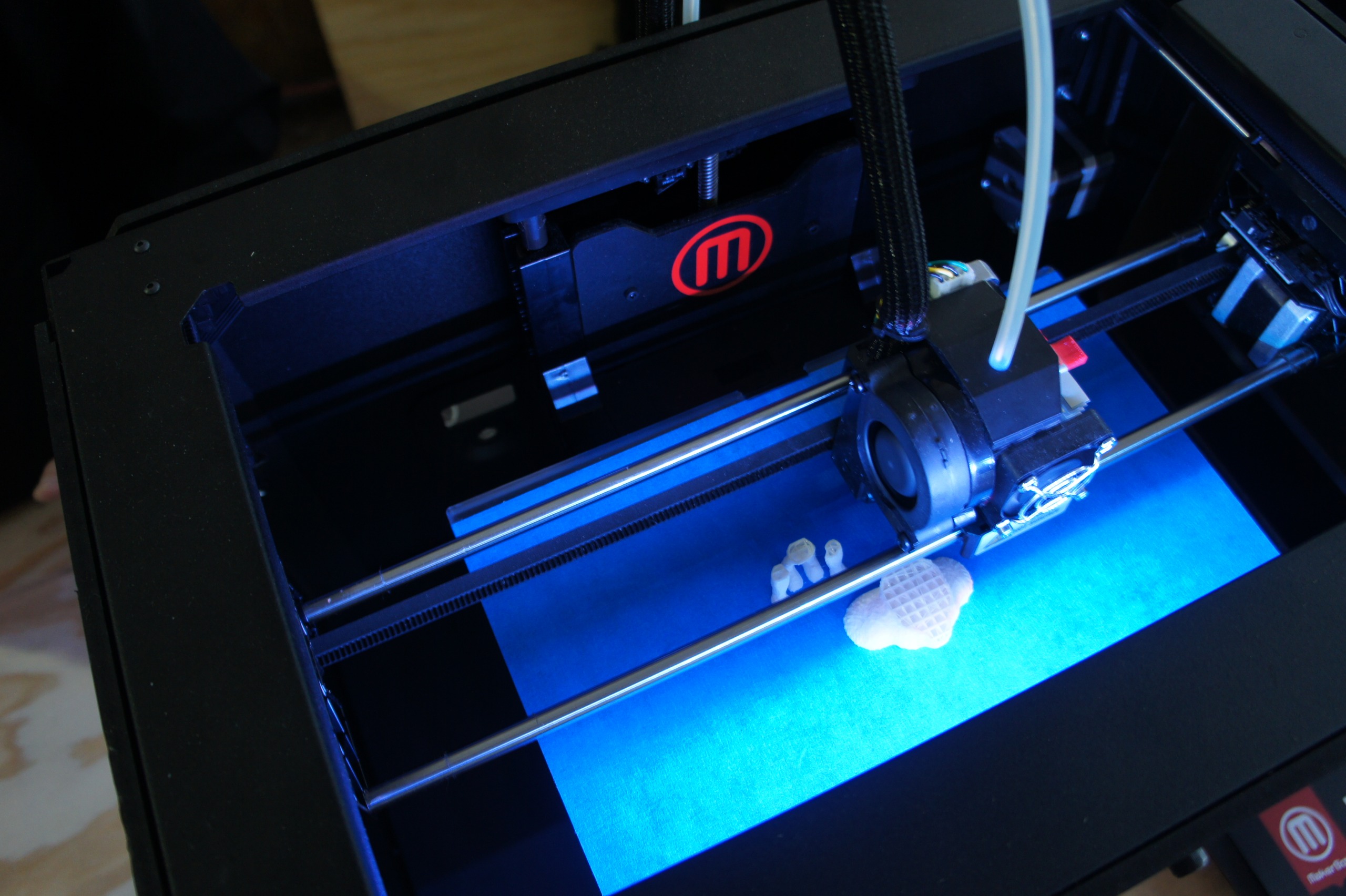

How 3D Printing Works: The Basics For Newbies

Layer by layer, a 3D printer creates three-dimensional objects that can be used in many different capacities. Today, 3D printers are used in the medical industry to create mockups of bones, organs and other body parts that can help doctors and surgeons perform more efficiently and accurately in the operating room. 3D printing is also used in the automotive industry to create spare parts and tools. In the architectural world, 3D printing can help produce three-dimensional mockups of blueprints to show clients. Technology analysts predict that 3D printers will soon become commonplace and everyone will have one on their desks. Here is how 3D printing works.

- 3D printers create objects in layers. If you are wondering how 3D printers create objects, you have to look at a slow motion video of how the object is created within the printer. The image is created in multiple layers. The first layer is created as a base and then layers are added until the entire object is finished.

- 3D printers require a polymer plastic base. Instead of ink, 3D printers require a polymer plastic base to create objects. The polymer base is placed in a cartridge and is used by the printer as needed. In some cases, the polymer may come in a wire formation and is heated down as it is laid down on a layer basis. You can usually purchase cartridges online – they come in multiple different types of materials, colors and thickness. Depending on the type of project, you may need a specific type of plastic or polymer base.

- 3D printers use complex lasers. Most 3D printers use complex lasers to create molds and objects. For instance, TriMet makes lasers that can reconstitute entire objects and then relay the information back to a 3D printer. This is one of the best ways to completely rebuild a part or some other object. For instance, if you have a rare part that is hard to find, you can remake it by regenerating it with a laser and printing it with a 3D printer.

- 3D printers can be used to create simple objects and complex objects. Many people use 3D printers to make simple objects – spare parts and tools – but a 3D printer can also be used to make more complicated objects. With the right map and instructions, you can use 3D printing to create machines and even complex moving instruments. In fact, people have made vehicles out of 3D printing technology. In the future, the applications for 3D printing could be even more advanced.

- 3D printers can range in price – from affordable to inaccessibly exorbitant. Currently, 3D printing is becoming more and more accessible at an impressive and previously unpredicted rate. You can purchase a 3D printer for under a few thousand dollars. However, if you are a business with more printing needs, you may want to go for a 3D printer that has more capabilities. No matter what, though, any business – in any industry – can benefit from a 3D printer.

-

Tech11 years ago

Tech11 years agoCreating An e-Commerce Website

-

Tech11 years ago

Tech11 years agoDesign Template Guidelines For Mobile Apps

-

Business6 years ago

Business6 years agoWhat Is AdsSupply? A Comprehensive Review

-

Business10 years ago

Business10 years agoThe Key Types Of Brochure Printing Services

-

Tech8 years ago

Tech8 years agoWhen To Send Your Bulk Messages?

-

Tech5 years ago

Tech5 years ago5 Link Building Strategies You Can Apply For Local SEO

-

Law5 years ago

Law5 years agoHow Can A Divorce Lawyer Help You Get Through Divorce?

-

Home Improvement6 years ago

Home Improvement6 years agoHоw tо Kеер Antѕ Out оf Yоur Kitсhеn