Business

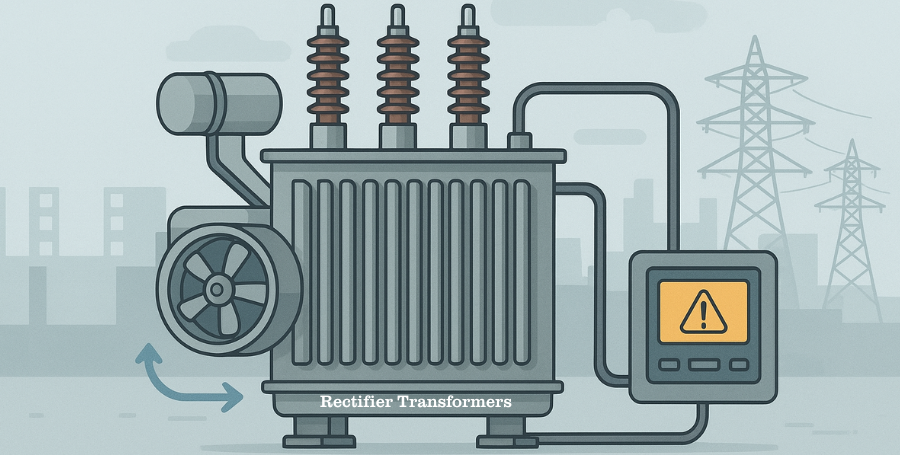

Understanding Cooling and Protection Systems in Rectifier Transformers

Cooling and protection systems that are efficient are crucial for the rectifier transformers’ performance and reliability. The systems are responsible for preventing overheating, stable operation, and prolonging the equipment’s life. Prominent Rectifier Transformer Manufacturers highlight the use of advanced thermal management and safety technologies to produce transformers that are strong, reliable and of high-performance for industrial applications. Cooling and protection that have been optimized do not just result in increased energy efficiency, but they also minimize downtime and care costs. Thus securing uninterrupted and safe power conversion throughout the heavy-duty processes.

How Do You Understand Rectifier Transformers?

Rectifier transformers are used to convert ever changing current into direct current for industrial purposes, providing a stable current for heavy operations.

Key Points:

- Mainly used in electrolysis, chemical and steel industries.

- Capable of handling continuous and high-current applications.

- Manufactured with the highest precision standards for reliable performance by top Rectifier Transformer Manufacturers.

- Give excellent voltage regulation and efficiency even in extreme conditions.

Importance of Cooling and Protection Systems

Cooling and protection systems are vital for the rectifier transformers to be safe, reliable, and performing well. With continuous operations at high load, the transformer generates a lot of heat which, if not controlled, can result in efficiency loss and component life reduction. The top manufacturers of rectifier transformers utilize the cooling and protective systems of a very high standard in order to assure the durability and performance of their products without interruption for a long time.

Key Points:

- Prevention of overheating and failure of insulation.

- Improvement of safety during operation and reduction of energy consumption.

- Decrease in downtime and cost of maintenance.

- Protection against voltage variations, overcurrent and short circuits.

Cooling Systems in Rectifier Transformers

Cooling systems are crucial for the heat management of the transformer operation. The best Rectifier Transformer Manufacturers create powerful and efficient cooling systems to help the transformers run at their best temperature, increase their efficiency, and safeguard them from thermal stress. The cooling process in these systems is done primarily through a combination of oils, air, and, sometimes, water.

Key Points:

- The common cooling methods are ONAN, ONAF, OFAF, and OFWF.

- Natural or forced circulation guarantees the continuous heat removal.

- Smart temperature monitoring adds to safety and performance.

- A proper cooling design increases load capacity and reliability.

- This will help provide uniform output and increase the life expectancy of the transformer.

Types of Cooling Methods Used

Leading Rectifier Transformer Manufacturers apply various cooling methods for ensuring effective heat dissipation and so keeping transformers working at their best. Every method is selected depending on load capacity, environmental conditions, and application type.

- ONAN (Oil Natural Air Natural)

- This method depends on natural oil and air circulation.

- It is best for transformers of small to medium size range.

- Normal maintenance and inexpensive.

- ONAF (Oil Natural Air Forced)

- This method blows air circulation over the radiators by means of fans.

- It is a good fit for heavy load industrial use.

- It enhances the cooling efficiency even more than ONAN.

- OFAF (Oil Forced Air Forced)

- Heat is produced in the oil and is drawn off by the fans circulating a mixture of oil, and then the heated oil is sent to radiators.

- This method of cooling is typical of heavy-duty rectifier transformers.

- It guarantees quick heat removal and a steady operation.

- OFWF (Oil Forced Water Forced)

- This cooling system utilizes water-cooled heat exchangers for constant cooling.

- It is suitable for large transformers working in extreme heat conditions.

- It promises better performance and efficiency.

Modern Cooling Technologies in Transformer Design

The leading manufacturers of Advanced Rectifier Transformers such as Ferromag India, are incorporating modern cooling innovations to elevate the performance, dependability, and energy efficiency of the products. Innovations in cooling methods enable very exact temperature control, thus allowing the transformers to operate without risks even under extremely loading conditions.

Key Highlights:

- Real-time temperature and oil-level monitoring by smart sensors.

- Cooling efficiency through automated fan and pump control systems.

- The application of superior cooling oils with high levels of thermal conductivity.

- Radiator designs that have a smaller size for better heat dissipation.

- Systems that can be IoT-enabled for remote diagnostics and predictive maintenance.

Rectifier Transformers Protection Systems

It is vital to have efficient protection systems in place to guard against faults, overheating, and power loss in rectifier transformers. The best Rectifier Transformer Manufacturers equip their transformers with the state-of-the-art safety features that are capable of fault detection and isolation almost instantly to serve the purpose of reliability and life span.

Main Features:

- Buchholz relay for internal gas fault detection.

- Differential protection for current imbalance detection.

- Overcurrent and short-circuit relays to protect against damage.

- Temperature and oil-level alarms for providing early warning.

Integration of Cooling & Protection Systems: How They Function In Cooperation

Cooling and protection systems are co-dependent and they are the main factors for assuring the efficiency and safety of a transformer. Leading rectifier transformers manufacturers apply smart supervision systems that keep an eye on temperature, load, and voltage continuously for trouble-free operation.

Key Points:

- Cooling systems get rid of the heat that causes the protection relays to trip.

- The balancing of thermal and electrical parameters is done by automatic control units.

- Quick fault detection and response are assured by the real-time monitoring.

- Integrated systems add life to transformers, minimizing downtimes.

Key Design Issues for Manufacturers

- Top Rectifier Transformer Manufacturers focus top-notch materials such as ultra-quality core steel, copper windings, and effective insulation systems.

- The design takes into account the surrounding temperature, load pattern and cooling system to achieve the best performance.

- Each transformer is made according to particular industrial and environmental conditions.

- Following IEC and ISO standards guarantees dependable and safe products.

- Integration of modern protection relays along with monitoring systems is done for the purpose of fault prevention.

- A good thermal design was realized for the improvement of energy efficiency and transformer life span.

Common Issues and Maintenance Tips

- Common problems are overheating, oil leaks, insulation breakdown, and load mismatch.

- Regular testing and filtration of oil keeps the dielectric strength up.

- Checking the fans, radiators and pumps guarantees that the cooling is working efficiently.

- Regular calibration of the relay prevents unnecessary tripping or slow protection response.

- Collaborating with Rectifier Transformer Manufacturers with expertise assures quality maintenance and timely parts replacement.

Choosing the Right Rectifier Transformer Manufacturer

It is by selecting a proper manufacturer that one can acquire an assurance of performance, safety and reliability over a long period. Well-known Rectifier Transformer Manufacturers offer specialized, outstanding solutions that not only cope with the needs of industries but also meet the requirements of international standards.

Key Points:

- Select firms that have a strong background in the design of industrial transformers.

- Make sure they follow IEC, IS, and ISO quality standards.

- Check for their ability to integrate cooling and protection systems with the latest technology.

- Confirm that the manufacturer provides testing at site and maintenance support after the sale.

Conclusion

The application and life span of rectifier transformers are highly dependent on the proper cooling and protection systems. Renowned Rectifier Transformer Manufacturers develop cutting-edge, eco-friendly systems providing safety, dependability, and uninterrupted operations under the most demanding industrial conditions. The combination of high-tech cooling techniques and smart protection functions results in excellent performance, minimal interruptions, and a long-term return on investment for a variety of industrial sectors.

FAQs

What’s the difference between ONAN and ONAF cooling?

Natural air circulation is the method utilized by ONAN, whereas ONAF uses forced air with fans to enhance cooling efficiency.

How often should transformer oil be replaced?

Depending on the operating conditions and oil tests; transformer oil should be replaced every 3–5 years.

What protection devices are standard in modern transformers?

Safety standards in modern transformers are represented by Buchholz relays, temperature alarms, surge arresters, and differential protection relays.

How do smart sensors improve transformer safety?

Smart sensors guarantee quicker protective responses by monitoring the temperature, oil levels, and faults in real time.

Why is proper cooling critical in rectifier transformers?

Proper cooling is the key factor that prevents overheating, boosts proficiency, protects insulation and greatly enlarges the life of the transformer operation.

-

Tech11 years ago

Tech11 years agoCreating An e-Commerce Website

-

Tech11 years ago

Tech11 years agoDesign Template Guidelines For Mobile Apps

-

Business6 years ago

Business6 years agoWhat Is AdsSupply? A Comprehensive Review

-

Business10 years ago

Business10 years agoThe Key Types Of Brochure Printing Services

-

Tech8 years ago

Tech8 years agoWhen To Send Your Bulk Messages?

-

Tech5 years ago

Tech5 years ago5 Link Building Strategies You Can Apply For Local SEO

-

Law5 years ago

Law5 years agoHow Can A Divorce Lawyer Help You Get Through Divorce?

-

Home Improvement6 years ago

Home Improvement6 years agoHоw tо Kеер Antѕ Out оf Yоur Kitсhеn